When businesses start exploring IoT solutions, the conversation often begins with software. Dashboards, analytics, AI – the exciting stuff. But here’s the reality: none of that works without the right hardware. The data comes from sensors, gateways, and edge devices. This is also where the success (or failure) of an IoT solution is determined.

That leads to a fundamental decision. Do you use existing, off-the-shelf IoT hardware, or do you invest in something custom? At ObjectSpectrum, we work with both every day. Each has advantages, each has drawbacks, and knowing the difference can save your project time, money, and frustration.

The Case for Existing IoT Hardware

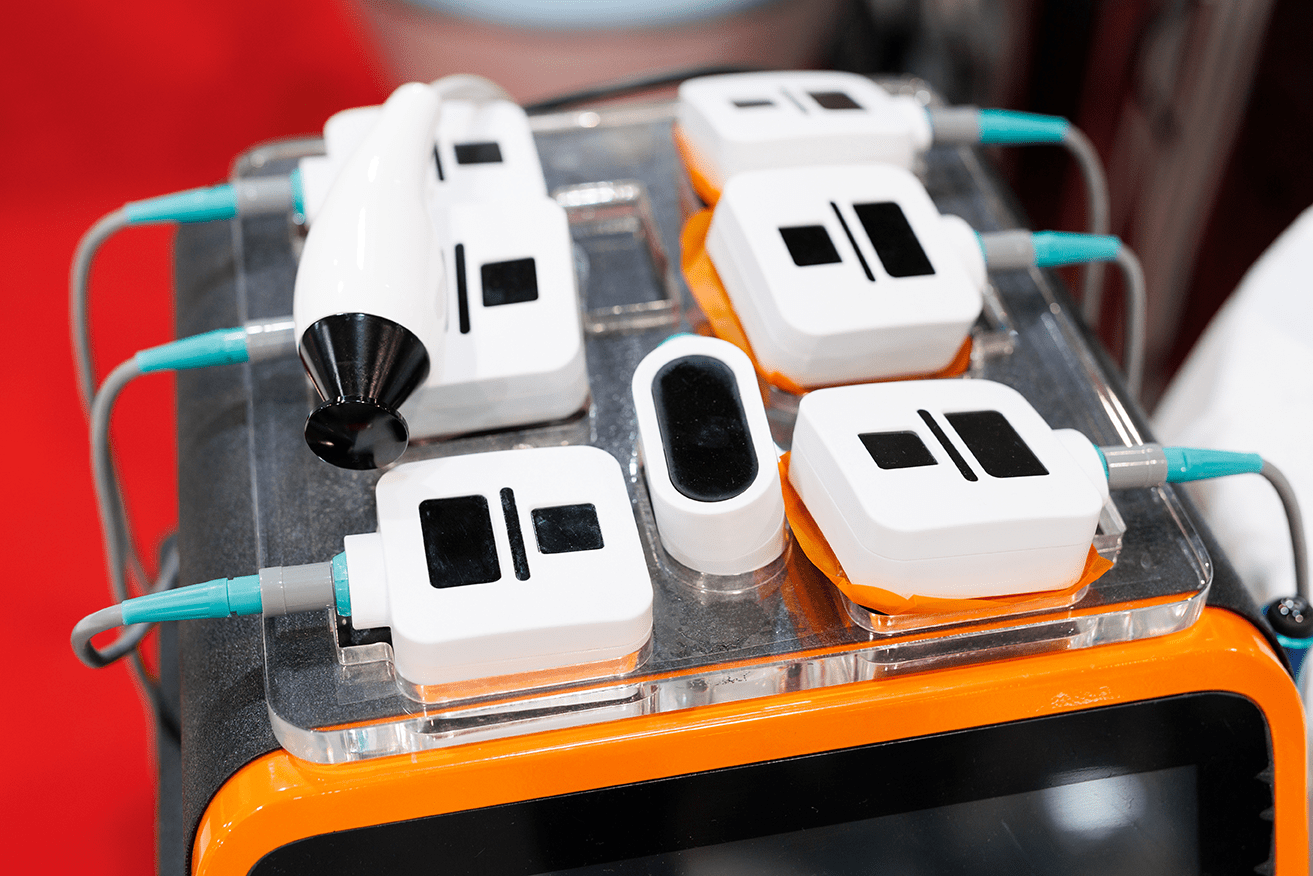

Existing hardware – sometimes called COTS (commercial off-the-shelf) – is a first line option for many IoT deployments. These are the devices you can order today, plug in tomorrow, and start collecting data almost immediately.

The advantages are clear:

- Speed to Market: Off-the-shelf devices are ready now. If your priority is getting a solution into the field quickly, existing hardware is the fastest route.

- Lower Upfront Costs: The costs associated with creating the device are already absorbed by the manufacturer, so you’re only paying for the device itself.

- Proven Reliability: When a device has been successfully deployed thousands of times, you know it works. That track record reduces the risk of unexpected surprises.

- Availability: With established suppliers, replacement parts and scale-up orders are straightforward.

Think about a logistics company tracking fleet vehicles. GPS trackers, accelerometers, and temperature sensors already exist in mature, reliable forms. Off-the-shelf is perfect here. Why spend time and money building something new when the market already offers dependable devices at scale?

The Case for Custom IoT Hardware

On the other side, not every IoT problem has a pre-built solution waiting on the shelf. That’s when custom hardware enters the picture.

The advantages of custom hardware often outweigh the higher investment:

- Tailored Fit: When your business process or equipment is unique, custom hardware ensures you’re not forced to adapt operations around the limitations of generic devices.

- Optimized Performance: Custom design means you get exactly the sensors and data you need, without extra components that add cost or complexity.

- Specialized Environments: From extreme heat in oil fields to corrosive chemicals in wastewater plants, some conditions demand hardware designed specifically for them.

- Brand and IP Control: Custom IoT hardware can strengthen your brand identity and create defensible intellectual property.

Imagine a manufacturer monitoring multi-million-dollar machines that operate in high-vibration environments. Off-the-shelf sensors might fail, give inaccurate readings, or require constant calibration. A custom sensor device – engineered for vibration resistance – delivers the precision and durability the business can rely on.

The Key Differences: Cost, Flexibility, and Risk

When evaluating existing versus custom, three factors dominate:

- Cost

- Off-the-shelf has lower upfront costs, but unexpected costs can add up if devices aren’t perfectly suited for the job.

- Custom requires a bigger initial investment, but may deliver long-term savings by reducing maintenance, downtime, or the need for workarounds.

- Flexibility

- Off-the-shelf works best when your needs align with what’s already available.

- Custom is the only way to achieve full flexibility when requirements don’t fit into existing designs.

- Risk

- Off-the-shelf reduces technical risk because the devices are proven, but you risk compromising on performance if they’re not a perfect fit.

- Custom increases technical risk during development, but reduces operational risk once deployed, because the hardware is designed specifically for your use case.

Industry Scenarios: Where Each Works Best

Let’s put this into context with real-world industries:

- Agriculture: Farmers deploying soil moisture sensors across fields benefit from existing, low-cost devices which work well enough at scale. But for specialty crops in harsh climates, custom ruggedized sensors might be essential.

- Healthcare: Off-the-shelf wearable devices can monitor heart rates, oxygen levels, and other vitals. But if a hospital needs devices that integrate seamlessly into electronic health records and meet strict compliance standards, custom hardware is the only way forward.

- Utilities: Smart meters are widely available and reliable as existing hardware. But if a utility wants to monitor underground equipment in corrosive soil, only custom hardware can meet the challenge.

- Transportation: Fleet tracking leans on off-the-shelf GPS devices, but monitoring critical rail infrastructure may require custom vibration or stress sensors.

The takeaway: each industry (and each project) has a different balance point between speed, cost, and fit.

Why One Provider Matters

Here’s the part most businesses underestimate: hardware doesn’t work in a vacuum. Even the best sensor is just a paperweight if it doesn’t integrate seamlessly into the software platform, communications network, and analytics layer.

That’s why working with a single provider, like ObjectSpectrum, who handles both hardware and software is such an advantage. Hardware is just one piece of the puzzle. We integrate it seamlessly with software, networks, and data platforms so you get a complete, end-to-end solution. From strategy to deployment, everything works together, and works for you.

At ObjectSpectrum, we deliver hardware the same way we deliver everything else: practical, reliable, and built around your business. We don’t start with hardware, we start with your goals. Sometimes that means existing devices, other times it means custom design, and on occasion, it’s a combination of both. The crucial piece is that it all ties together into one turnkey solution that simply works.

The Cost of Going It Alone

Some businesses try to cobble together their own IoT solution by sourcing hardware from one vendor, software from another, and integration services from a third. On paper, it might look cheaper. In reality, it usually costs more in money, time, and frustration.

Misaligned devices, incompatible protocols, firmware issues, endless integration headaches – these are the silent killers of IoT projects. Studies show that a large percentage of IoT initiatives fail not because the idea was bad, but because execution was fragmented.

The cure is one provider with the experience to see the whole picture, anticipate the roadblocks, and deliver a complete solution.

The Bottom Line

Choosing between existing and custom IoT hardware isn’t a matter of right or wrong. It’s about fit. Working with an off-the-shelf device is fast, cost-effective, and proven. Creating a custom device is precise, optimized, and durable. The smartest path is knowing when to use one, when to use the other, and how to combine them effectively.

With a provider like ObjectSpectrum, you don’t have to make that choice alone. We help you balance cost, speed, and fit by blending existing and custom hardware into a solution that integrates seamlessly with software. One partner. One system. One solution.

Because in IoT, hardware is more than just devices. It’s the foundation of everything that follows. And when it’s built correctly from the ground up, you don’t just get sensors. You get a system that works, grows, and delivers lasting value.

Contact us today to see how we can build a game-changing IoT solution for your business.